Why Do Stage LED Displays Require Die-Cast Aluminum Cabinets?

Stage-grade LED displays commonly utilize die-cast aluminum cabinets as the primary structural material for key display modules. Unlike conventional advertising applications, stage rental display equipment must meet requirements such as high frequency, high intensity, and rapid installation and disassembly. Die-cast aluminum cabinets are well-suited to these demands due to the following six advantages:

Lightweight Design for Easy Installation and Transportation

Stage LED rental screens require frequent transportation, installation, and dismantling. Heavy cabinets not only increase transportation costs but also hinder the efficiency of stage setup and teardown. Die-cast aluminum cabinets weigh only one-third as much as traditional iron cabinets, significantly reducing handling difficulty. A single operator can easily handle installation, greatly improving operational efficiency and reducing labor costs.High Strength and Precision for Excellent Flatness

Stage performances demand extremely high flatness for background screens, as even minor irregularities become noticeable under lighting, compromising visual effects and aesthetic appeal. Die-cast aluminum cabinets offer robust structural integrity, withstand frequent assembly and disassembly, and are manufactured by injecting molten aluminum into precision molds. Subsequent CNC machining ensures dimensional consistency, resulting in a seamlessly flat display surface when assembled.

Quick Assembly Mechanism for Enhanced Efficiency

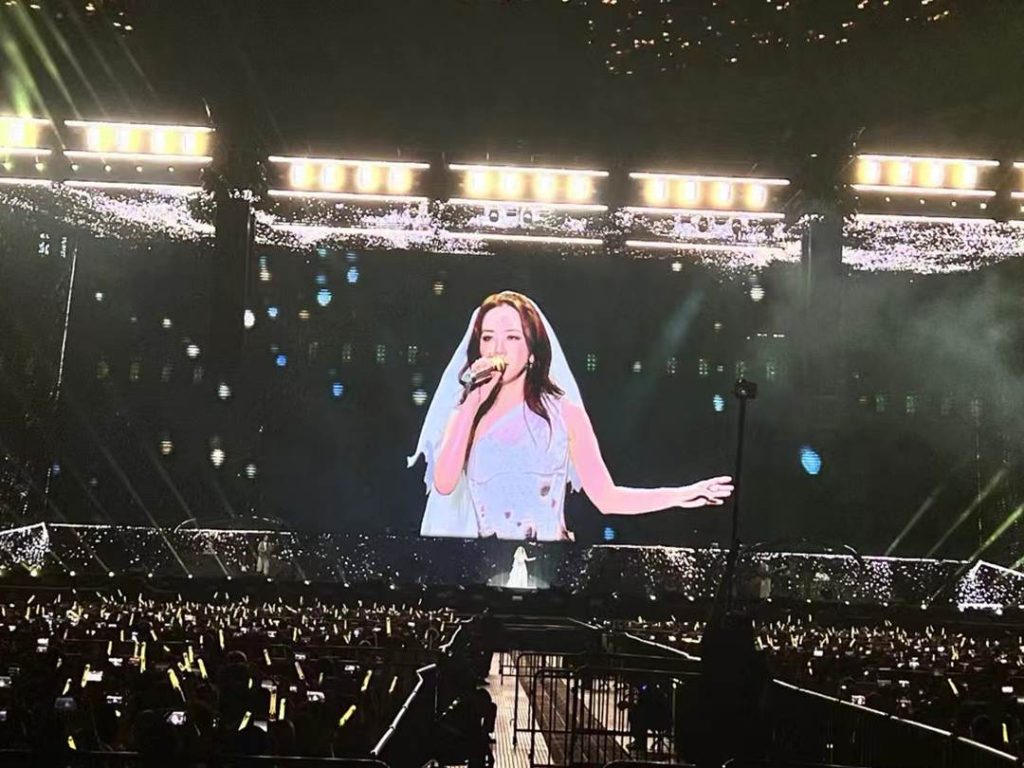

Events such as wedding celebrations, galas, concerts, and live shows often operate under tight schedules, requiring fast yet reliable cabinet connections. Die-cast aluminum cabinets can integrate high-precision quick-lock mechanisms, allowing installers to rapidly connect cabinets without extensive tooling, significantly reducing setup time.Superior Heat Dissipation for Stable Performance

Stage LED displays typically operate at high brightness levels for extended periods, generating substantial heat. Inadequate heat dissipation can lead to premature LED degradation, reduced brightness, or even failure, adversely affecting display quality and lifespan. Aluminum alloy, an excellent thermal conductor, allows die-cast aluminum cabinets to act as large heat sinks, efficiently absorbing and dissipating heat from modules to maintain optimal operating temperatures, thereby enhancing device stability and longevity.

Excellent Sealing Performance for Versatile Environments

Stage performances occur in both indoor and outdoor settings. Although events are typically scheduled to avoid rain, sudden weather changes or dust exposure may still occur. The smooth surface and precise dimensions of die-cast aluminum cabinets, combined with sealable joints, provide high-level dust and water resistance, ensuring reliable performance in diverse environments.Aesthetic Appeal and Durability

Die-cast aluminum cabinets often undergo surface treatments such as polishing, sandblasting, and anodizing, yielding a premium finish with strong wear resistance. This makes them ideal for high-end applications like stage performances, where both visual appeal and durability are essential.